Quality Metal Spare Parts by Customized Metal Stamping for Electricals and Telecom

Custom Laser Cutting Bending Precision Metal Cabinet Stamping Parts Production information Our products Company Profile

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | Merid 2010 |

| Surface Processing | Powder Coating, Polishing,Galvanized,Painting, etc |

| Fine Blanking | Multi-Position |

| Process | Separation Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.01mm |

| Customized | Customized |

| Transport | by Sea, Air or Express |

| Part Type | Stamping Parts |

| Color | as Per Customers′ Requirements |

| Service | Customized and Standard |

| Technics | Stamping |

| Production Drawing | Provided |

| Application | Agricultural, Automotive, Household Appliance etc |

| Export Markets | Global |

| OEM | Yes |

| MOQ | Sample Order Is Acceptable |

| Surface | Powder Coating, Polishing, Galvanized and So on |

| Lead Time | 7-30 Days Depends on Quantity |

| Process Method | Blanking, Punching, Bending, Forming, Finishing |

| Standard or Nonstandard | Nonstandard/Customized |

| Product Name | Metal Stamping Parts |

| Transport Package | Pallet, Wooden Case, Paper Carton, Iron Case |

| Specification | As per customers′ requirements |

| Trademark | Merid |

| Origin | China |

| HS Code | 7308900000 |

| Production Capacity | 100000pieces/Month |

Product Description

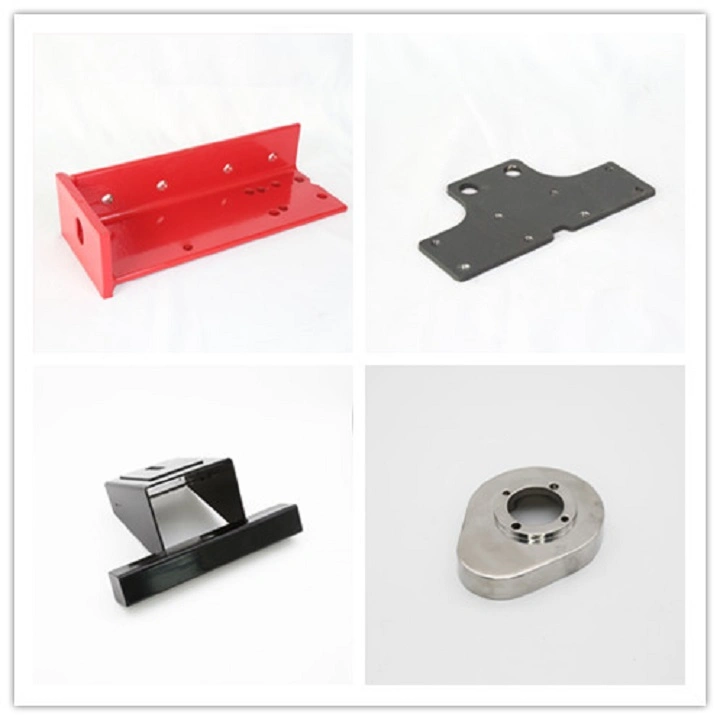

Custom Laser Cutting Bending Precision Metal Cabinet Stamping PartsProduction information

| Model NO. | Customized | Tolerances | 0.01mm |

| Product name | metal stamping parts | Finish | Powder coating, anodizing, paint, zinc plated and etc |

| Color | As per customers' requirements | Trade mark | Merid |

| Package | Wooden case, paper carton, pallet, iron case | Market | USA, UK, German, Japan, Netherlands, Australia, Mexico, Sweden, and so on. |

| Origin | Made in China | Production lead time | 7-30 days. |

| Description | |||||

| Material range | Carbon steel, iron, alloy steel , stainless steel, aluminum alloy; brass, copper, bronze, copper alloy ect. | ||||

| Surface | Powder coating, paint, hot dip galvanized, electro galvanized, chrome plated, nickel plated, polishing etc. | ||||

Process | Metal fabrication, machining, welding, forming, shaping, drilling, stamping, laser cutting, CNC lathe, CNC milling, spot welding, full welding, tig welding, mig welding, riveting, tapping, grinding, assembling, etc. | ||||

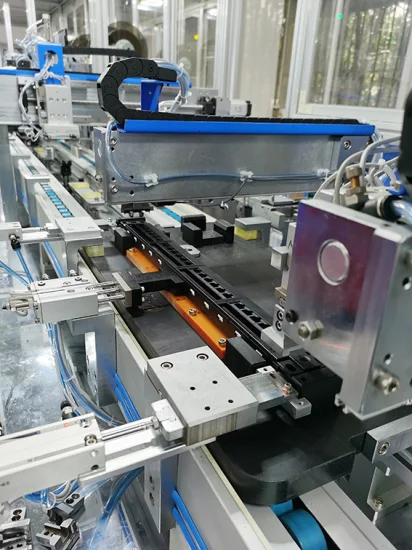

| Machinery | 15-500ton stamping machine, CNC lathe, CNC milling, band saw cutter, auto welding robot, butt welding machine, beding machine, plate cutting machine, shot blasting machine, drilling machine, polishing machine, flame cutting machine. | ||||

| Our capacities | stamping, welding, maching, casting, forging, assembly, surface treatment, deep drawing etc. | ||||

| Service | OEM&ODM | ||||

| Material thickness | 0.5mm ~12mm, or as per customers' requirements. | ||||

| Application range | Construction, agricultural, automotive, electric, sports accessories, furniture, household appliance etc. | ||||

Company Profile

Qingdao Merid Machinery Co.,Ltd is an ISO certified custom metal parts manufacturer, established in 1991, providing custom metals parts in Stamping, Casting, Machining and Welding for a variety of industries and applications, including Medical, Automotive, Agricultural, Farming, Architectural and other industries.

Merid offers comprehensive in-house services, from initial design to fabrication. For over 27 years, Merid has established a good reputation for meeting customers' requirements and quality standards as a custom parts manufacturer.

Our strong team is dedicated to providing you the world-class quality and service, our team includes professional engineers and designers, skilled tool makers, experienced QC inspectors, well-trained machinists and management personnel.

Package

QC equipments Our ExhibitionWhy choose us?

1) We have our own factory, quality can be controlled seriously and price is very competitive.

2) We have been manufacturing metal stamping parts for nearly 30 years..

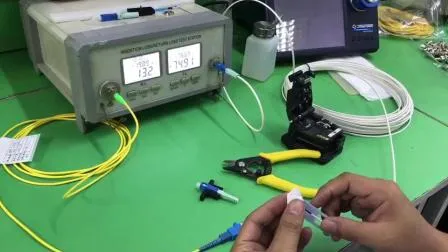

3) We have professional testing equipments and quality control personnel.

4) We have own R&D department experienced technicians.

5) On timely delivery and 24/7 service.

FAQ

Q1: Are you a trading company or a manufacturer?

We are manufacturer, established in 1991 with trade team for international service.

Q2: How long is your delivery time?

Normally, the production lead time for sample is 10-15 days and lead time for the mass production order is about 30 days as per quantity.

Q3: How long will it take for quotation?

Within one working day if drawings are available.

Q4: Do you offer samples?

Yes, samples can be provided to check and test.

Q5: Which countries are your main markets?

America, Canada, Mexico, Europe, Australia,German, Netherlands and so on.

Q6: Do you have experience of doing business with overseas customers?

Yes, we have over 10 years exporting experience and most of our products are exported to overseas market. We specialized in the high quality custom metal parts.

Q7:How about the quantity guarantee?We will make 100% inspection before packing and shipping .If you have any during using, pls contact me and i will reply you in time .